Description

Professional new wood thicknesser MOTO530

Specification

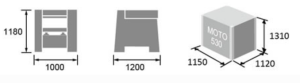

| MODEL | MOTO 530 |

| Max. working width x height |

530x300mm |

| Cutterblock diameter | 120mm |

| Max. cutting depth | 8mm |

| Feeding speed | 5-20 MT/l’ |

| Number of knives | 4°-30x530x3 N°mm |

| Cutterblock rotation speed |

4800g/l’ |

| 3-phase motor power cutterblock |

7,5HP (5,5KW) |

| Work table dimensions |

1050x532mm |

| Min. working length | 280mm |

| Power of the motor for feeding |

0,75HP (0,55KW) |

| Power of the motor for rise/fall |

0,5HP (0,33KW) |

| Extractor port Dia. | 170mm |

| Net/Gross weight | 800/870kgs |

Feature

|

Variable speed infeed by inverter suit for all types of finish required. |

|

Cast iron table mounted on 4 heavy pillars for excllent support and accurent without any locking. |

|

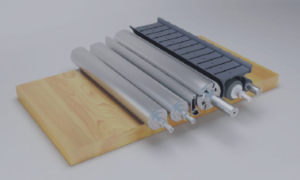

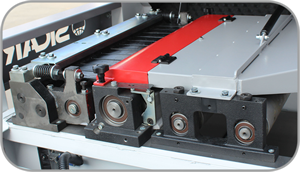

Spring-loaded pressure bars and double out feed rollers design prevent vibration of very thin work pieces during thicknessing. |

|

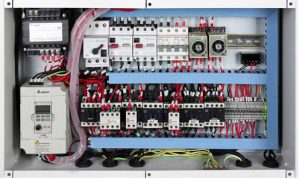

Professional electrical box. Frequency conversion control feeding speed. |

|

Independent module, bringing better strength and higher stability. |

|

Plc control + magnetic grid induction help to reduce positioning time and high precision. |

1.Spiral infeedroller guarantees an efficient feed motion of the wood and a good quality.

2.4 sturdy columns support the thicknesser.

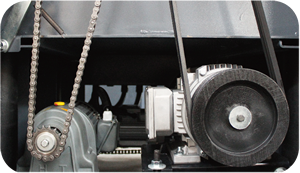

3.Stepless feeding of the wood: speeds of 5 to 22m/min.

4.Frequency conversion control feeding speed.

5.Every system (up and downfeeding and outputmain shaft) all have independent motor.

6. Both PLC automatic control and Manual control.

Real Live Photos

More about wood machinery MOTO 530 planer thicknesser price , Feel free to contact us.