Description

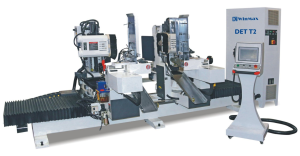

Woodworking machine Double sided round double end tenoner

Specification

| MODEL | DET T2 |

| Max.material size | 2000mm(L)x180mm(W) x70mm(T) |

| Max.working thickness |

70mm |

| Max.working width | 180mm |

| Max.tenon length | 40mm |

| 1st Spindle power | 5.5KWx2pcs |

| 2nd Spindle power | – |

| Spindle speed | 12000RPM |

| Feeding motor | 400W(SERVO)x2pcs |

| Length movement | 1KW with Reducer(SERVO) |

| 1st/2nd Spindle up / down |

1.0KW(SERVO) x2pcs(X1 &X2) |

| 1 st/2nd Spindle right / left | 1 .OKW(SERVO) x 2pcs(Z1 &Z2) |

| 1 st/2nd Spindle forward / backward(depth) |

– |

| Working pressure | 0.6-0.8Mpa |

| Total power | 18.30KW |

| Dimension | 4600x2200x1800mm |

| Weight | 2500kg |

Feature

1. Automatic feeding and discharging; advanced numerical control system, simple operation, easy adjustment, high degree of automation.

2. Automatic clamping positioning, double end simultaneous processing, efficient and accurate, reduce labor intensity of workers.

3. The separation of the knives effectively prevented the workers from industrial accident.

4. Production of square, rectangular tenon, waist circle, circular, oblique tenon shapes, are widely used in door, table, chair and other furniture tenon processing.

5. Technical breakthrough the vertical swing angle, (+45°)(-12°), the horizontal swing angle (+13°)(-23.5°) range, 5-6 times of single head tenon work efficiency, saving labor cost.

6. Automatic alignement of worked pieces on guides situated in front of the operator, who is in the best position both to collect pieces and to control their quality.

Possibility to cut off, adjusting the thickness to “0”

More Details for cnc double end tenoner machine