I want to come to you with 10 things that make a CNC woodworking business.

And if you want to know more about CNC Router business,check this post《10 Tips for Wood CNC Router Business》.

No.1 High Demand.

Personally, I’ve experienced a overwhelming amount of demand and opportunity out there. I’m gonna get into the specific areas here down on the list a little further. But one thing that I always say”if there is no demand, nothing else matters”.

No.2 Low Startup

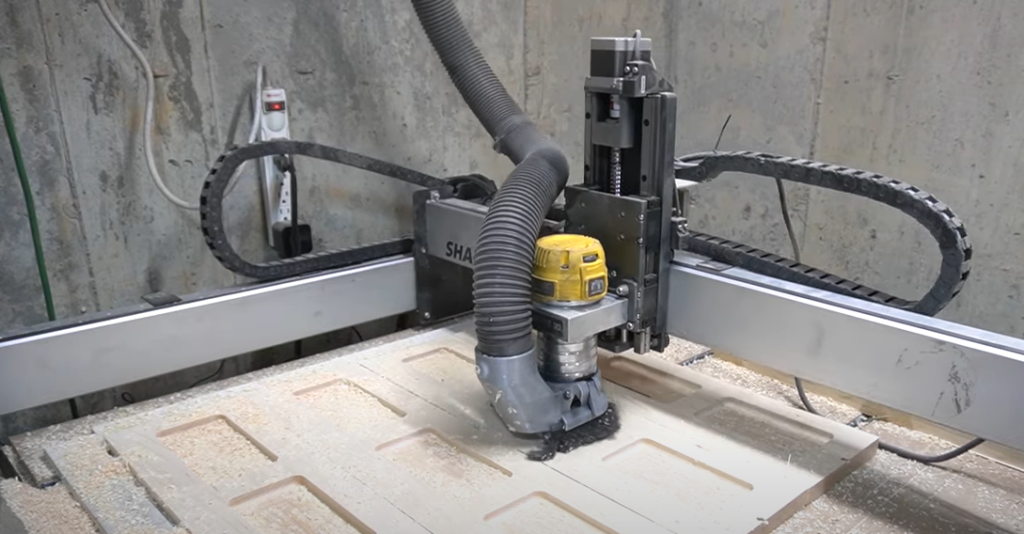

There’s two things with that doesn’t take a lot of space and it doesn’t take a lot of extra money. Now you have to invest some money to startup. But once you’re up and going you’re off to the races.My first shapoko was the xxl which fits comfortably on a 4×4 table and it was in the corner of my basement. I also could go in a garage really easily and what you have to put into it to get started is very little compared to the income potential that it offers.

No.3 Easy Workflow

When you’re doing any kinds of project you’re going to develop a workflow. Now CNC machine is no different and it actually is a lot easier to develop a workflow. Because everything’s kind of broken into steps. You can break it down really easily.

Why that’s so big when you’re doing a sidehustle? Is this your full-time job, so you’re gonna get pulled away a lot and you’re going to be able to go in after your day job in the evening and be able to pick up where you left off and not have to figure out.

I’ve got to figure out where I start or where I left off. It’s going to really easy to be like. I left off here and now I can pick up right here.

No.4 Repeatability.

It can take time to come up with designs and products and prototypes and that whole process can be time consuming, but once you get those products and prototypes, you can cut them over and over again.

So there isn’t the redesigning each product every time. If you’re unable to come up with product ideas or struggling to come up with design ideas. Don’t worry. That’s not a limiting factor in this whole things. Because there are a lot of templates and a lot of kind of design files that people have designed that you can either purchase or there’s a lot of free ones out there and carbide create, makes it really easy to import those and get coding right away.

No.5 Fast Turnaround

This is similar to repeatability, but a little more specific. In today’s day and age, people want things quick.And the CNC machine is able to do that. So assuming you already have all your files and your products ready to go say you have four or five products and someone approaches you and says”I want one of those, but I want my name on it “or “something along those lines”.

In a short period of time you can have that product turned around and to the customer. That is a huge advantage in today’s fast-paced market.

No.6 Custom Work

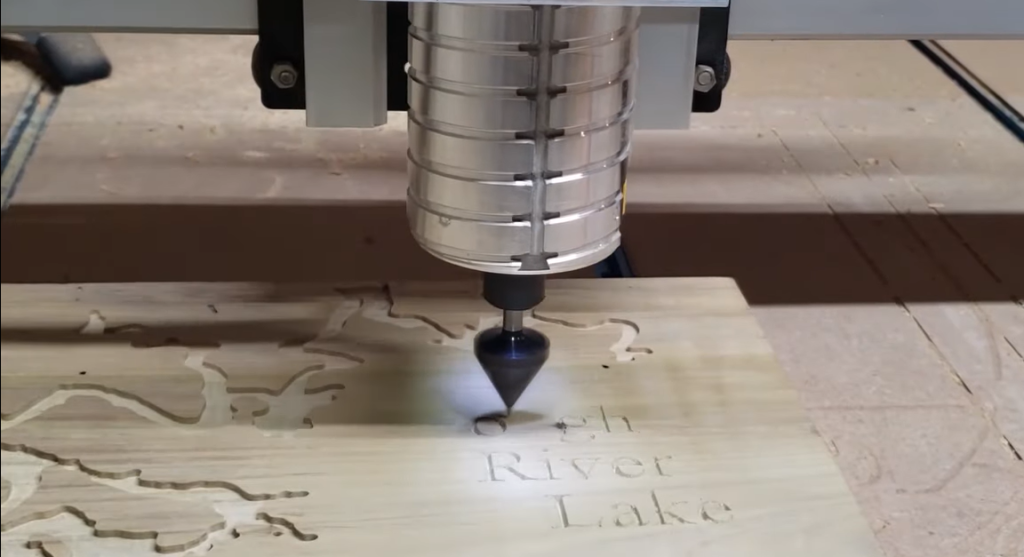

The reason why this makes a great potential sidehustle is custom work.There are a lot of different kinds of custom work out there. When I’m talking about custom work, I’m talking about usually one-of-a-kind pieces, whether that be a 3d topography landscape, whether that be a a custom sign with different sayings on it.

Theres’s a million different types of custom work out there, but the nature of the custom work is usually more one-of-a-kind pieces uh. They take a little more time to design because of that, and but you can usually charge more for those pieces. So here’s an example of a custom piece that I’ve done, and this was a sign that they wanted the us army logo on it. They wanted their name, they wanted the year it was established and they wanted it as a a custom bar sign.

This was a really kind of a quick custom design, but I’m not going to make 50 of these. I’m not going to make 10 of these. I’m only going to make one of these lynch’s pub signs.

No.7 Wholesale Work

This is where I’ve had a lot of success and I’ve spent a lot of my time.So if you think about it most of the products that we purchase aren’t made by the company that are selling them. So I took that same philosophy and really tried to reach out to retailers that had established presents and sell directly to them for a reduced rate. Now the nature of this is less complex designs at a higher production rate.

Here’s an example of a wholesale product that I’ve made hundreds of. This is a walnut soap, dispenser tray that I made for a retailer that i sold at a wholesale rate directly to them. This is the way it came off the CNC before any finishing was done now.

I would put a larger piece of walnut on the CNC bed and in an hour I can produce six of these. Like I was saying highly replicable easy designs and producing a lot of them.

No.8 Personalizing Products

so you can purchase cutting boards from a Big box store and personalize them, so it’s not like you have to make a cutting board and have all the tools to make a cutting board. You could do that, but you can purchase products and put someone’s name on them. Put a logo or a recipe, there’s a lot of opportunity there.

No.9 Selling Items Seasonally

This is really cool, because a CNC business really isn’t about momentum,where a lot of other sidehustles kind of. If you stopped in the middle in another business, you might lose that momentum.

Well, with a custom, CNC woodworking business, you can only sell it christmas. You can just make christmas items so maybe for two or three months, you’re running the CNC and you can profit really well just when people are buying things. You know you don’t have to sell in january february where things are a little lower. It might not be worth your time.

No.10 Passion Projects

If you have a hobby or an interest in something specific like topography or maps, you can make things like that and sell them.

How cool is it that you can make things with your shipoko, that you have a passion for and that like-minded people will find them awesome too. And they’ll want to support you in what you’re doing.

Those are 10 things that I’ve learned over the last three years since purchasing my shapoco.