Welcome back to Winmax woodworking and

our manufacturing facility and we are going to talk about 4×8 CNC Router ATC with vacuum table.

2022 4×8 CNC Router

We’re going to be covering the new and exciting features, the auto tool change and spindle for the 2022 4×8 CNC system.

If you haven’t done, so already head on over to our website to check out detailed post on the new machine design and the new CNC controller.

Spindle

Now the spindle is a 6 horsepower. That means it’s going to run off of a 220 single-phase power source. You don’t need a three-phase power source or even a phase converter, but it still has all the power you’ll need for cutting.

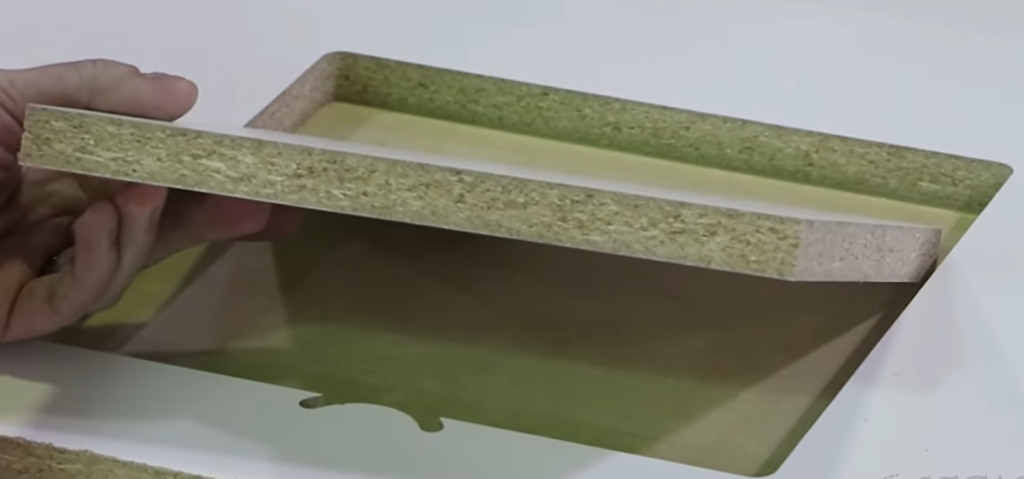

Tooling

The tooling is ISO 30, and it comes as an ER 32 collet size. Now this tooling you can order specifically in different collet sizes from ER25 all the way up to ER32s.

Now an ER32 will accept up to a 7 8 shank diameter cutter.And all cutters from that size.Even down to one millimeter can be accepted into the spindle.

By combining the horsepower and the tooling, we increase your cutting speeds and your cut per pass, which it greatly increases your productivity.

If you’re already familiar with CNC, you understand the importance of a powerful spindle.

If you’re not familiar with CNC, you can see this cuts. Parts faster than you can on your table saw and with a better quality finish.

The spindle can be programmed up to 24 000 rpm, which means you can match the perfect feeds and speeds and chip loads for the different materials you’re cutting.

It also rotates in the clockwise and counterclockwise rotations, which accommodates for left hand and right hand spiral cutters in the market place now.

Obviously, the spindle is auto tool change, but we can run it in a manual tool change mode up to 100 cutters, but sometimes you just need to run one tool.

The spindle requires a dry air supply of 110 psi. Now this performs a couple of tasks, including cooling, the spindle and performing the auto and manual tool change procedures and the cone clean during those procedures. It also opens and closes the dust extraction system.

Air Cool Systems

The nice thing is air cool systems require less maintenance.

Auto Tool Change

Our most requested feature for the maverick 4×8 system was auto tool change.This system has a six tool change position, allowing you to start your programs, walk away to continue other tasks and come back to see a finished part.

More tools

Winmax’s auto tool change feature is pretty exclusive. We are able to run a program that has more tools than the actual tool holders on the machine.

For example, let’s say we had a program that required 8 tools to run a part when it gets to tool No.7,the machine will automatically come to the manual tool change position, so we can insert tool No.7 and tool No.8 manually.

Choose Manual and AutoOption

Normally we’d have to break up a program into two separate programs, but this allows us to choose either option.The ability to switch from manual tool chains to auto tool change is very useful.

For example, let’s say you accidentally did not place a tool holder in the tool clip or for any reason the spindle is unable to automatically pick up the tool. When the system senses this problem, typically you’d have to just stop the program and start over.

But when this happens, the system will automatically switch to manual tool change mode, allowing you to complete the part. After the part is completed, you can then resolve any issues with the tooling.

Dust Collection for CNC Router

We recommend 1500 CFM for the dust extraction system.It also has a six inch port here at the top. The brushes can be opened and closed manually at any time so that you have access to the tool.

It also is controlled automatically during all CNC operations. Now you don’t have to compensate between auto tool, change, capability and respiratory safety.

More details about best cnc router bits for wood and CNC Router Machine,just to our website at working-machinery.com ,or just WhatsApp us on+86 13923391045