Today I want to share with you 5 reasons to add a bandsaw to your workshop.

After that I’ll share with you The features of this Winmax 16 inch bandsaw.

5 Reasons to get a Bandsaw

And I’ll tell you what I like and what I don’t like and what I would change If I could.

Cutting Curves in Wood

Cutting curve parts could be anything from just needing to cut a curve profile on things, making tulip bases for tables if you’ve seen those.

Making Curves Table Leg

And then making stuff like this unique looking table leg, you can do nowhere else, other than a band saw not easily anyway.

As you can see, I didn’t really even lay out any lines here.I just basically drew sketched a rough draft and then just kind of roughly cut it out.

Everything would take my time because it doesn’t really matter the shape you’re cutting. It’ll work out every single time to make a really cool looking leg like this.

That would make a phenomenal looking table leg and then you could cut 3 more to match that if you actually laid them out.

I wanted to just kind of give you a proof of concept, there’s actually a video by woodworkers companion. I think that’s the name of the channel I’ll drop a link in the description that shows you how to make these.

He done tables and a bookshelf that looks like it’s melting based on the same concept. Extremely easy to do on a bandsaws as you just saw.

That’s one thing: a band saw would offer to your shop that you can’t do on anything else.

Making Reindeer

Another thing I recently did was made Winmax this reindeer. It’s made out on a bandsaw.

And it’s basically made from the shape of a two before so inch and a half thick by three and a half inches wide.

There’s templates available again link in the description to the where I got them from same place. That shows you how to do those legs. Ad it was really really easy to do.

There was one spot I had to take it to the smaller wind band saw because I didn’t at the time, didn’t have a thinner blade to put on here. I’ve since ordered some, but it’s a really cool project that you can do with the bandsaws.

Milling(Rough Cut Wood)

I’ve had this really gnarly piece of white oak for quite a long time. I actually had several slabs. They had this really crazy little divot in every one of them, and there wasn’t a whole lot. You could do with them other than trying to slice off pieces.

That’s what’s really good about a bandsaw too is when you get rough things like this, you can actually break them down into smaller, more usable products. So you can actually make something out of it.

As you can see, I was able to cut that really quickly with the bandsaw. Now I have this piece that I could actually joint or plane down and actually use this piece of white oak.

I could have cut that on the table saw, but what that does is introduce that clay in there. That could actually cause a kickback and it’s extremely dangerous.

You’re not going to get any kickback using a bandsaw.

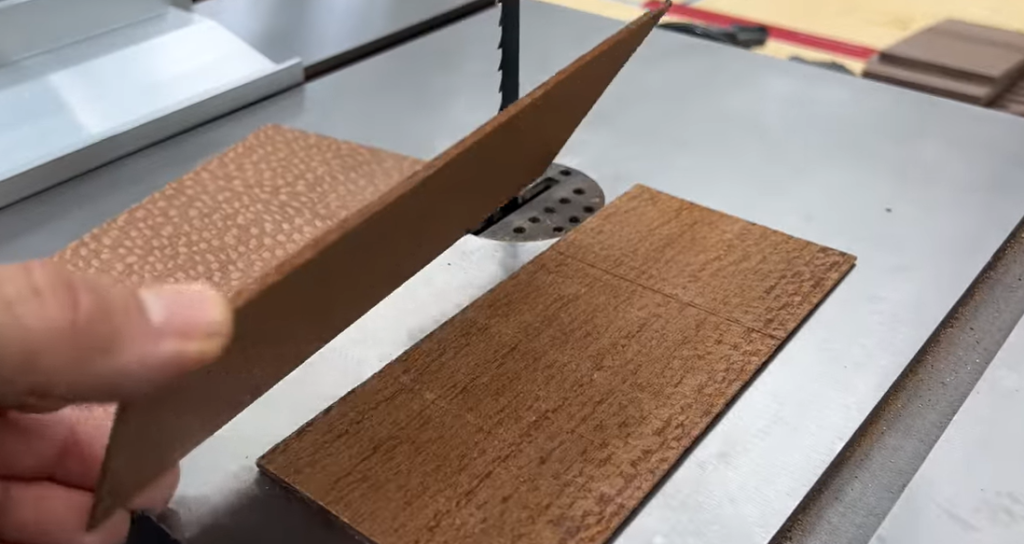

Resawing(Thicker Stock)

That’s the main reason you’d want a bandsaw there is to actually do resawing and cutting thicker stock into thinner stock.

Is this perfect? No, I could have done a little better job. If I took my time, I could use the fence as well, but I also like just using kind of following the line.

I can get those both exactly the same, whether we use a planer sled or something to run them through the planer.

Then I have two equal pieces that are much thinner than the other piece that I was going to use.so coasters, making boxes or veneers. You cut veneers with this as well. It’s just an all-around tool that is super handy to have in the shop.

Cutting Clean(Notches in Wood)

The bandsaw is perfect for cutting out notches just like this.

You could do it on with a jigsaw, but most likely you’re going to have a lot of tear out unless you tape or figure out some other way to prevent that jig saw blade, that’s going up and down to tear out plywood.

It really will make a mess of things well, the band saw is always cutting down, and so you basically it’s not a zero clearance.

You can make a zero clearance for it, but it will leave a very super clean cut, as you can see here just awesome and you can get that perfect notch without any saw kerf underneath like if you use the table saw or some other method.

Cutting Out (Small Parts)

Another excellent use for a bandsaws is to cut out small parts if like on this CNC project I’ve got here. I was able to cut those little tabs out really easily with a bandsaw.

That took me like a minute to cut those out, maybe less and it’s super clean, it’s a good clean cut.

I can sand what’s left there, it’s just a multi-function tool that you’re going to use once it’s in the shop you’ll find yourself using it all the time.

What I Like About the Winmax Bandsaw

Resaw Capacity of Bandsaw

One thing that I really enjoy about this saw is,it has 13 inches of resaw capacity, meaning this arm will raise up and give you 13 inches of clearance.

This is a 24 inch bandsaw, which means there’s 24 inches of clearance between this bar this upright and the blade.

Dust Collection of Bandsaw

I really like the dust collection on here, as you can see, underneath there’s very little dust that actually collects under there. If you have a four inch dust hose coming out now, I did have to add this adapter just so that my quick connect would actually reach that.

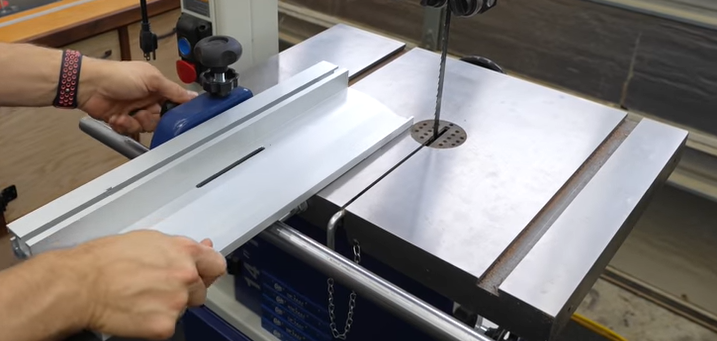

Fence of the Bandsaw

A couple of things I really love about the saw is the fence. The fence is a low and a high.

It’s super easy to change from low to high and it’s also extremely easy to square up to the blade, especially if you have something like these fast fence alignment system tools from carter.

45 Degrees of Table

The table will tilt up to 45 degrees, so you can actually cut bevels and things like that on there.

It’s extremely easy to change the blade out these doors pop right, open this lever on the back, unloosens the tension, and then you can just take the blade off put a new one on get everything set.

Tool-less Blade Guides

I really enjoy the fact that these are tool-less blade guides that you can just loosen this off and it will pop right out. You can push it right, close to the blade you don’t want it touching.

There’s a really good video on how to set up a band saw. I’ll drop it in the description below by sondergrass. I think his first name’s alex that keeps the blade tracking correctly.

Window of the Band saw

You see here there is a window where the blade is? Would you actually see if it’s tracking correctly on that top wheel? There is also a tension meter, which I really wouldn’t trust that very much If I were you.

How to’s for all Band Saws

As a beginner, big bandsaw guy, I got a tiny one over there. But as a using a bigger one. One of the things I really appreciate about Winmax is on the inside of the top door. They give you some how to’s for all band saws, how to choose correct number of teeth.

Diagnose problems, install your blade like it’s a really handy guy. That’s right! There you’re not gonna lose it because it’s stuck to your saw and on the bottom. It tells you the length of blade you need, for this saw it’s 111 inches and it’ll take 3 16 up to three quarters, so you know exactly what kind of blade to get for your saw.

110 Volt

One of the main reasons I chose this specific model is it’s 110 volt, meaning it will plug into any outlet I have in the shop. I’ve got one 230 or 220 outlet, and the saw is connected to that table saw.

So I wanted to make sure I could use this anywhere in the shop.

The Start and Stop Buttons

The start and stop buttons are really conveniently located on the left side, easy to get to easy to press.

It comes with a really nice bladeI did go ahead and pick up some extra blades, some thinner ones, so that I could do curves tighter curves and things. But it comes with a really nice probably a quarter inch blade that, or three quarter inch blade that you can do resawing with straight out of the box.

Back of Band saw

On the back there’s 110 volt outlet that will power up when you plug it in.

You can add a light or anything like that. If you wanted to also it has a convenient tool holder for all the allen keys that go with the saw, so you can actually have them on there and not lose them.

I like the scale on the side that tells you about where you’re, at up and down when you’re, lowering and raising this blade guard overall fit – and finish of this is kind of a pebbled feel it’s all metal. You can stick things to it.

Just a super solid feeling machine. I specifically chose this model because it has the storage underneath that I can actually store my blades and parts and pieces to the bandsaw. All in this one place

If you’re still here, I’m starting a channel on Youtube you go check that out. That’s where we’re going to share some woodworking and the machine running for your ref. If you want to check us,pls click Winmax YouTube here.

And you can also check Winmax LinkedIn here