Welcome to WINMAX and we are going to talk about edge banding machine.

Preparation for full automatic edge banding machine operation

- Clean the machine and the workplace and check whether the vacuuming system is working properly.

2. Check whether the glue in the glue pot is sufficient and clean.

If it is insufficient, glue should be added appropriately according to the amount;

3. Adjust the position of the balance bar according to the length and width of the workpiece;

4. Adjust the distance between the upper pressing shaft and the lower track according to the thickness of the workpiece.

Ensure that the workpiece can be pressed steadily, and will not crush the workpiece surface because of too tight;

5. Adjust the size of the plastic door, so that the edge material can be coated evenly and fully;

6. To test machine to see whether the edge banding machine is working properly or not.

7. Prepare materials and accessories (pad, paper, etc.).

Automatic edge banding machine operation process

- Heat the rubber wheel to 180℃, and open other switches when the indicator light is on.

When edge banding, glue pot temperature should be kept at 180℃±20℃, glue shaft should be kept at 200℃±20℃;

2. Install edge banding material, and put the workpiece on the conveyor belt, close to the 90° guide rail baffle, and then push evenly in parallel;

3. When prrocess a workpiece, must be do the first self-inspection;

4. To make special-shaped workpiece edge banding, first use 240# sandpaper to burr.

When in special-shaped edge sealing machine operation, pay attention to uniform force.

Six solutions to affect edge banding quality

There are many factors that affect edge sealing quality of edge bander, such as edge banding work being interrupted, interfering with time measurement and affecting the reliability of man-hour application.

There are several methods to improve the efficiency of work and improve quality:

1. If the local edge sealing strip fails to firmly bond with the edge of the plate, it can be repaired with glue;

2. If necessary, tear off the edge sealing strip, saw off or milling off the edge banding;

3. When found that there are rust spots on the board, wipe the machine with anti-rust oil in time;

4. Maintain edge bander, especially the glue coating device of edge banding machine;

5. The cooperation between the process and working procedure (such as the first drilling plate or door strip group edge sealing, etc.), to be clear that bad cooperation will also have adverse effects;

6. The performance of the edge banding machine (such as track speed), the position and height of the workpiece, the speed of the operation of the workers and the judgment and processing ability of the fault, the operation of the workers will affect the normal use of the edge sealing machine.

Therefore, necessary training should be carried out before workers take up their posts.

If you want to minimize the impact of interruptions on working hours, please try to use skilled workers to operate.

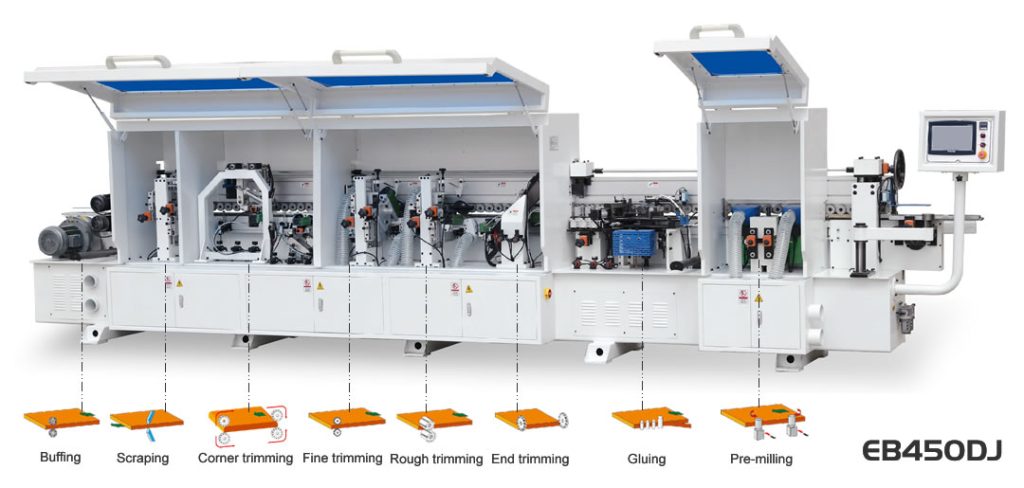

EB450 Series automatic high speed caterpillar edge sealing machine, suitable for medium and large custom furniture enterprises

Detailed steps for edge banding and Wood veneer cover

1. Edge banding:

Use manual or automatic edge banding machine, no matter which kind of, the program of edge banding are the same as below:

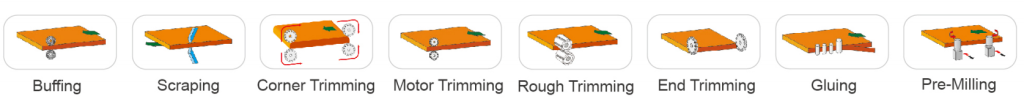

Glue on Plate edge or edge band–Press edge band to plate edge–End trimming–Fine trimming–Buffing.

For automatic edge banding machine, there will have more as premilling, rough trimming, corner trimming and scraping etc.

The key point of edge banding is that the plate edge should be straight, there is no stair cause by cutting by sliding table saw.

To press tightly, otherwise there will have gap between edge band and the plate.

It is better to use edge banding special glue when manual, as use all-purpose glue which will be easy to fall off in heat.

2. Wood veneer cover:

Plate wide belt sanding–veneer selection–veneer cutting–veneer jointing–plate gluing–placed the veer on the surface of the plate coated with glue–put into the hot press pressing–end trimming or corner trimming

A few key point to wood veneer cover:

The surface of the board must be smooth, and there shall be no ribs, depressions, holes, etc.,

Otherwise it is easy to have bubble and separate;

Veneer cutting mouth should be straight and tight seam, otherwise it is easy to crack;

The glue should be appropriate and uniform, too much glue is easy to pass through the glue, too little glue is easy to have bubble and layer;

Hot pressing temperature and time should be accurately grasp.