Welcome to Winmax and we are going to talk woodworking machinery.

Talk about the pros and cons of the 3 different levels sizes of CNC Router Machine.

I have the unique experience of owning CNCs 3 different sizes and actually running a CNC based business.

So I want talk about the pros and cons that I have seen with my CNC Routers and I’m also going to talk about a game changer, which is to me the competitive advantage that each CNC router machine has over the other one and kind of why I went from a small desktop CNC to an industrial type CNC.

Small Desktop CNC Router Machine

Pros Small CNC bmachine

First things on these mini desktop CNC Router we’re going to go over the pros.

Hobbiest/Weekend Warrior

A small CNC router is going to be great for your hobbyist. If you’re a weekend warrior, you have just a small side hustle, and it really helps out your side hustle right. This is not going to be you’re not going to base a large business off of a small CNC mahcines.

Indexpesive $2k-$6

With that being said, it’s going to be relatively inexpensive. It’s probably going to cost you two thousand to six thousand dollars somewhere in there, which is relatively inexpensive .

Small Footprint

It’s gonna have a smaller footprint. So that’s a good pro. It’s gonna have a smaller footprint. You can probably put it in your basement. If you’re really feeling risky you can put in office space in your house, in your garage. You know it’s it’s pretty small, so you can really fit it in a lot of different places.

Easy to Move

Another good thing about it, it’s lightweight! So it’s going to be easy to move. So if your wife gets angry at you for having it in your office or in the garage, and you need to move it to the basement, you and a couple friends can probably pick it up and move it with the larger type CNC’s. You know, unless you have a forklift in your house, you’re, probably not going to be able to move it right or if you have really strong friends.

Easy to Run and Maintain

Another pro about this, that it’s easy to run and maintain. So whenever you’re running this,it’s relatively easy.You’re probably going to have the learning curve, like every operator has.

Less Risky Learning Curve

But you know if you break something, it’s a lot less risky of a learning curve. So if you break something on this, you know it’s only going to cost you a little bit. It’s not going to cost you arm and a leg like on the bigger machines.

Great for Carving and Engraving

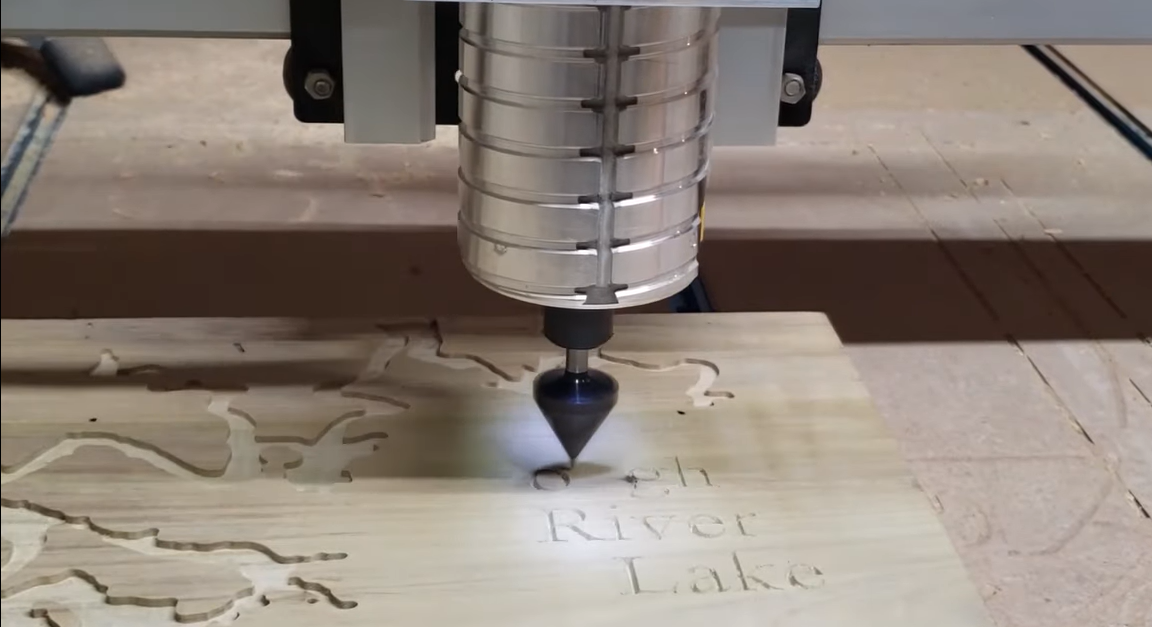

The biggest pro on this machine is that it can engrave pretty much anything; You’re not going to be able to run cutter heads and stuff like that super fast. But a huge pro is you’re going to be able to engrave anything or carve anything, and that’s what I think this machine is best for, and that is my game changer for this machine.

Game Change for Small CNC machine:You can compete with almost anyone doing small custom engravings.

If you’re just wanting to carve or engraved signs and stuff like that, this CNC is perfect. For that to me it can compete with any large machine on engraving because the feeds and speeds. It’s probably going to get to run at 60 to 90 inches a minute which this machine is well capable of. You can really compete with Small projects doing small custom engravings with somebody that has a larger type machine because you’re getting it done in the same amount of time. So to me, this is the game changer for this machine.

Con’s of Small CNC Machine:Many Limitations

Now, let’s talk about the cons, this machine has many limitations.

Table Size

For instance, it’s not a huge table.So you’re not going to be able to cut a sheet of plywood, throw it on here, you’re probably going to work on one to two small projects at a time.

Cutting limitations can’t use every bit available

You’re not going to be able to handle all the bits that are out there for CNC’s. Because this machine is not rigid enough, not powerful enough or anything like that. You know the max bit. You’Re, going to be able to handle properly is probably a 3 16 cutting bit. Maybe a quarter inch cutting bit, but for engravings and sign making you’re fine.

Lots od change outs

Another Con of it is you’re gonna have to change the bid out a lot. So you don’t have an automatic tool changer most likely on these type machines. So if you’re doing something that involves three different tools, you have to be there to change them out and reset the height and all that stuff, and that actually can take a lot of time.

Slowest of all sizes for cutting

Trust me from personal experience that takes a lot of time .

High chance of burning up these bits

You’re probably going to have a high chance of burning up these bits, because this machine is not capable of running at the proper speeds. And so, if you are using a quarter inch bit.

You’re probably not going to be able to run it at the speed. You need to run it at so you’re going to be burning up that bit, which is going to cost you a little bit more and in bit cost. But with that being said, the takeaways from this is that a great machine for engraving and carving and really learning about CNC’s how to get into them.

And this is going to save you later on if you take out your learning curve on this thing and you break a couple bits – and you maybe mess up a part here and there versus when you get to the more expensive machines.

4×8Fit 1325 Intermediate Level CNC Router Machine

Now let’s move on to the intermediate level CNC router,many people also calls it 1325 CNC Router. It has a four foot by eight foot bed: 3 horsepower spindle,some aluminum,steel, etc.

Pro’s of Intermediate Level CNC

Extreme Weeken Warriors

This CNC is good for like an extreme weekend warrior

Big Side Hustle to Small Business

Or if your side hustle starting to get a little bit bigger or you actually have a small business you’re running. This is a great compliment to that machine or to that business.

Nested Manufactuting

One of the biggest pros for this machine is that you can start doing nested manufacturing on it. So these intermediate level CNC’s typically can hold a half sheet.

Fit 1/2 sheet of full sheet

So they’re, either four by four or four foot by eight foot, so they either hold a half a sheet of plywood or a full sheet of plywood.

Great for Mass Engraving /Carving

Now you can start doing multiple projects and multiple parts at the same time and allows you to really get more quantity out without having to change small projects on that smaller change, more projects on that smaller CNC. Think of this CNC as like perfect for a sign shop, so it can do all the engravings that your smaller cnc can do.

But you’re engraving a longer boards or pieces of plywood. Now you can engrave multiple of those at the same same time, which is going to save you time and actually increase your profitability or increase your output, so that’s a huge deal. Most. A lot of sign shops actually have this type of cnc an intermediate level because they can’t justify going to the large one, because it’s intermediate level one satisfy all of those needs.

Easy to Run

Another pro this intermediate level, one is still probably pretty easy to use . It’s probably a pretty similar usability to that smaller type CNC, the computer system is going to be kind of similar, and it’s not going to be super high maintenance, similar to the smaller CNC and the learning curve is going to be about the same right. Parts are getting a little bit more expensive, but the learning curve is still going to be about the same and You know. So that’s a good thing.

More Regid

It’s a little bit more rigid. So the bits are going to vibrate a little bit less and you’re going to have a little bit, smoother cuts and all that good stuff. So this machine is a great upgrade from that smaller CNC and the only the couple downfalls of.

Con’s of the Intermediate Level CNC

I’ll get into the cons is the cost.

Getting Pricy $12K-$30k

You’re probably gonna be in the $12k to $30k range for something this size,something in the intermediate level which that’s a downfall.

Larger Footprint

Your footprint is now going to be bigger, so you better have a three-car garage or a big two-car garage or a huge basement to be able to put this machine in it. You may have to go for the 4×4 model instead of the 4×8 model like I have here.

Still Cutting Limitations

So you still have cutting limitations with this as well.You’re not going to be able to use a half inch bit or anything like that in this Machine. You’re still going to have some cutting limitations. You’re not going to be able to run a 3 8 bit bit to its maximum capacity. You’ll be able to run a quarter inch bit and you’ll have less limitations in that small bit, but you still don’t have unlimited access to all the bits in the CNC world and can run really any bit you’re still going to have some limitations. So that’s a pretty big con to this machine.

Less Fun More Business,But Still Having Fun.

Another one of the cons is that you know changing out parts is still pretty simple but you know if you jump from projects to project, with the overhead costs associated with everything, it’s costing you more for this machine to sit there versus that smaller machine to sit there and once again, you’re going to have a little bit Less fun, maybe than what that smaller machine is going to offer, because you’re you’re probably going to be worried about price a little bit and cost and using this machine so you’re getting a little bit more serious when you get this type of machine.

Game Changer: Larger Workspace for More products per Changeout

Now, the big and most important game changer and why i moved to this machine from my small machine – is because I needed to cut out more parts. So I need to cut out a lot more parts and my small machine. Just wasn’t cutting it . I had to start cutting out a lot more parts, so I went to this machine and I can easily justify the cost of this machine because of how many parts I needed to cut out.

During christmas and my busy seasons and stuff like that I’ll actually use this machine to engrave as it’s a very good machine to engrave sign shops use this. I ‘ll actually have both of my small machines engraving, along with this CNC right here engraving, which is really useful!

5×10Fit Industrial Type CNC Router Machine

So now we’re to industrial type CNC Router, which has a 5 foot by 10 foot bed, a steel welded frame and, like a 10 horsepower spindle on it that weighs like 80 pounds. Now this machine is when you start to run a legit company with quite a few employees, and you really start playing with the big boys.

https://www.youtube.com/shorts/HnTK_UORPoI

The funny thing was when was writing out all these pros and cons. There’s a lot more cons than I thought when I was writing this machine out or when I was actually purchasing this machine. So it’s kind of funny to look back at it and see how many cons there are.

Pro’s of 5×10 CNC Router Machine

Only the the different pros based off of the upgrade from that medium size CNC router to this large size CNC machiens. So with that being said, let’s go into the pros.

No Limitations on Bits or What you can do-High Speeds.

One of the biggest pros on this machine is that it’s able to run anything. You have no limitations on what types of bits you can use. How fast you can run it anything like that. The motors on this are big enough. The body is rigid enough to really handle anything you can throw at it, which is a huge pro.

Typically have ATC

It also has a automatic tool changer on it. So now I can change out up to 10 different bits in a single program. so I can run something and it’s going to run a v bit then to run an eighth inch bit and a quarter inch bit and a half inch bit then a certain type of half inch bit . It can do that without me having to stand here and change out the bits which is a huge Pro.

High Earning Potiential

It has very high earning potential as you may guess.

High output- meant for high production of homogenous products of materials.

Because this thing is meant for high output manufacturing. It’s meant to put on the same material over and over again and cut out either lots of parts or lots of the same type of product,by using the same bits and really just spit out as much product as possible. So if you can keep this machine busy, it’s going to make you a lot of money.

Nested Manufacturing

Also the nested base manufacturing on this machine is another pro.Because the vacuum table is actually strong enough to hold those parts down and the table is big enough to actually nest. All of those parts into the machine which is really cool.

It’s Beast! No Vibration,Clean cuts etc

It is also a beast , there’s no vibrations. It has really clean cuts and it’s really hard to emphasize that enough. How pretty your cuts are on this machine based off of everything else, because there’s no vibration and your your motors can actually handle everything that this machine wants to do. So it’s super cool .

Con’s of 5×10 CNC Machine

There’s a lot of cons with this machine.

Expensive $50k-$250k

The No.1 con, is the cost you’re probably going to be looking at on the very low end for the lowest end industrial grade CNC machining you’re probably looking at around fifty thousand dollars and the very high end industrial grade type CNC machine of this kind is about 150 000. There’s even higher grade CNCs that are going to probably be a quarter million dollars, etc. but those are going to start turning into different models or they have three or four heads. They have three or four tables working. They get pretty nuts. So you’re looking at probably 50 to 150 000 for an industrial type CNC machine like this.

Larger Overhead ,do not want this to Idle

You’re gonna have a lot of overhead with this CNC machines, because now you have to have a big shop for it.

Huge Footprint

So you have a large footprint, which is another con and a large overhead, which is another con. So the footprint is going to be a very big area and you can no longer keep that in your garage or in your basement, or anything like that. You better have a 20 car garage in order to keep this bad boy in there. You’re gonna have to start having specialized equipment to run this machine. I have a um a devoted air compressor for this machine, an air dryer for this machine, a dust collector that just runs for this machine, etc.

So if this machine is sitting here and not working, it’s technically taking up space and losing money because of all the electricity, all the overhead and all the space is taken up in your shop. So that’s a really big con on this machine is, if you don’t have enough jobs or anything like that, and it sits here for a month. You’re really just pouring money down the drain, which is not a good thing.

Huge Learning Curve

There’s a huge learning curve to this. So you know on the other machines the learning curve is not as risky as costly.

Parts are expensive and costly

On this machine if you break something,you’re probably going to be spending a couple thousand dollars versus the other machine, if you break something and maybe a couple hundred and that’s not a good thing.You think you know everything on those other machines once you get to this big industrial type, the computer interface gets a little bit more complicated.

Change out different size Material and Projects takes a lot onger

It gets harder to change in and out projects. If you don’t check something. You have 10 different bits.

Expensive Bits

You may have to check to make sure the height is right. You may put in the wrong tool and it may grab the next tool and then it could break something all that stuff can go wrong. So there’s a lot higher risk learning curve with this machine .

Not as Fun as Hobbiest

And the really the biggest con I would say with this machine is that you know the smaller entry level CNC’s. You can have a lot of fun with them. You can do some carvings and stuff, engravings, you do full fun, family projects etc. The mid-level CNC machine,you can kind of do the same thing. It gets a little bit more serious, but you’re still having fun, making cool projects and stuff like that.

When you get to this level CNC Router , it gets a lot more businessy and all the all the fun stuff you used to love to do on a CNC machineslike play around with the carvings and stuff like that. It gets either way too complicated. With this CNC or gets too costly, because the overhead into the CNC router so getting something like this, don’t expect to have as much fun as your smaller CNC’s. It’s going to be a lot more serious, but in return it’s probably going to make you a lot more money. So it’s just a just a trade-off between happiness and a little bit of money granted. I still have a blast on this machine, but i’ll tell you when i was starting out on on that smaller machine and learning that was probably the most fun i’ve had.

Game Changer:Its Speed and Cutting ability.

All in all , the game changer for me to getting this machine is, I needed to cut out parts faster, so that was the biggest game Changer the automatic tool changer and being able to run bigger bits faster, actually increased, my cutout time from that medium size CNC to this large CNC router by about 50 percent. So i can actually cut out 50 more parts on this CNC, as opposed to my medium size CNC routre , which is a pretty big deal if you’re a production shop now would i change the way i went about growing my shop right, so i started with a small Entry level CNC graduated to a mid-level CNC and ended up with this industrial type CNC machining and me at my age. I just turned 25 a couple days ago. You know i have a lot of experience with CNC’s a lot of first-hand experience with CNCs and business and production type stuff .

I would never trade that for the world,I think it is really good to start off smaller and then upgrade and then upgrade again because if you find the right path for your CNC, it’s going to pay for itself like that.

That’s kind of what all of my CNC’s do. I make sure i’m able to for them to pay for themselves relatively quickly, so i can justify the cost and justify the overhead etc. Now, with that being said, i have really big plans for cutting it close in the future.