I run a CNC business with my desktop CNC Router along with my website.

If you’re anything like me getting started is always the hardest part.

If you find yourself stuck on where to start to make products to sell.

The process of making products seems to be a pain point.

Like I said earlier, the hardest part is getting started. Because of that I put together a step-by-step guide that will help you get started making money with your CNC machine.

If you’re interested in that I’ll talk about it a little more later.

The Wooden Tray Prototype

This new wooden tray design that I’ve been working on revolves around this material, now I’ve taken a pretty much basic design tray and I’m trying to get this material to work.

This is a colored layered plywood. You can get it from a lot of different vendors, but it is baltic birch16 inch layers and you can get it in a lot of different colors. So let’s walk through these different prototypes from the beginning to the end and where I am now.

First Prototype

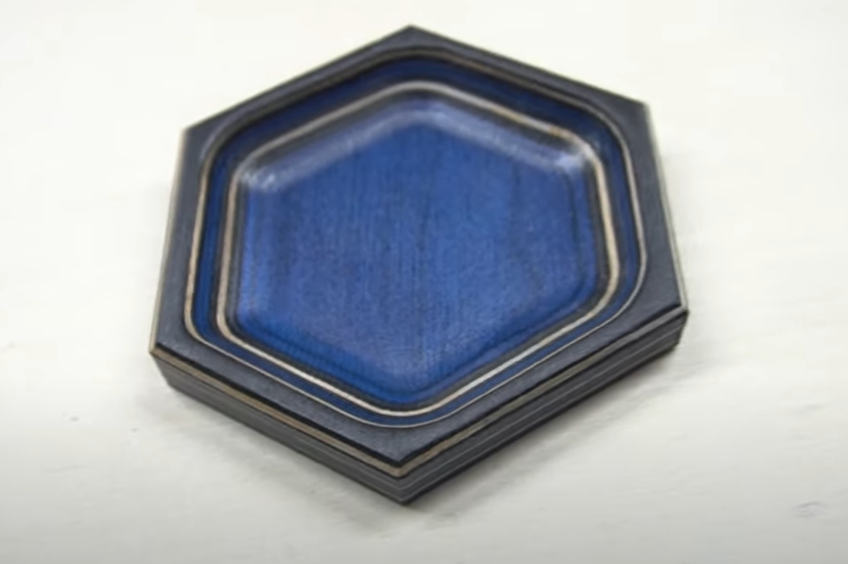

I’ve made these trays before out of different materials out of solid hardwoods, these hexagon trays, combining with this material I was like that would look really cool. So this is my first prototype.

I went a little smaller to save material and really wanted to see what it looked like. I like that. I was really happy with this progress and want to make it bigger.

I’m really happy with the machining. The first finish I tried was a oil based finish and I wasn’t really happy with the colors.

If you can see, these are really bright colors on the edges, I wanted to maintain those that brightness and it seemed when I used an oil-based finish. It darkened the wood too much. so I was like okay. I need to go with a water-based finish in order to maintain the wood’s vibrant color.

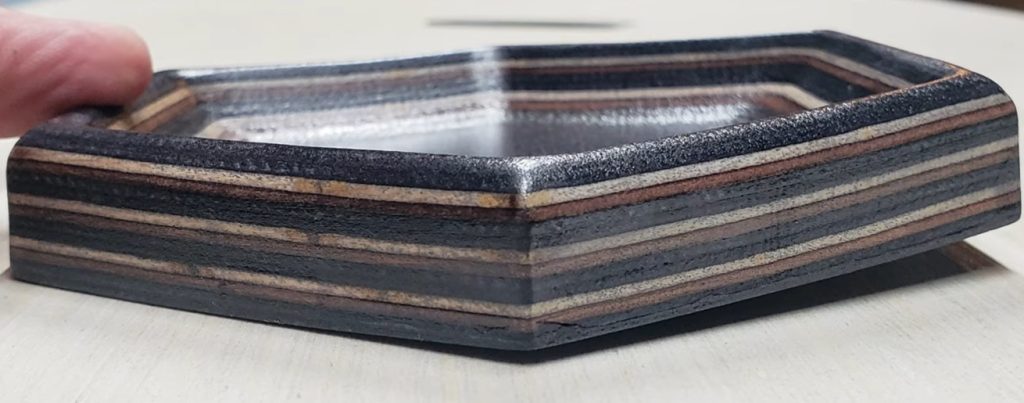

If you see the different colors here in the bottom, that’s because either the bed of my CNC machine or my z-axis or something is slightly out of square.We’re dealing with sixteenths of an inch here.

You really tell your weaknesses in your machines that usually you would not be able to tell so I fiddled around with it and tried to change some of the machining techniques and it just wasn’t worth the effort.

I learned from this was that I had to machine down to a point where there are at least two layers of the same color. This doubles my room for error from a 16th inch to an 8th inch.

One reason is important when developing products is you want consistency. So if I listed these on my website and they looked one color and then when someone ordered them and got two of them and they weren’t the same color, they could be upset.

So everything is cooking along and going fantastic. At this point, I was really excited about the progress that we made that I was like what I want a little bit more wow to it.

I never was really happy with the edges. So I designed this tray in fusion 360 and got a more gradual incline here. So what it does is it really displays those colors and layers. This looks extremely cool. I was really happy with it.

Material Price

Let’s talk about this material price just a little bit. This material is not cheap. I would have eight dollars in material cost in this one tray that is really high.

When I do a walnut tray, I have less than two dollars in the material cost. Now it is four times the material costs into this tray. That’s pretty significant when you’re thinking about rejects and errors. Eight dollars doesn’t include my time, machining, design, and any of that.

That’s just material cost. That was a little scary at first, but I figured if i make a unique enough tray. I can charge more for it. My plan was to charge thirty to forty dollars for this tray and that might seem ridiculous.

But if you do research right now, there’s a lot of hardwood trays that are 30 bucks which I think is ridiculous. I would never buy but I don’t determine the market.

I think that’s important thing to remember just because you wouldn’t spend it doesn’t mean that someone else won’t. This tray was actually my last prototype, and so I made a couple more of the same.

I was really excited and I sent them off to have professional pictures taken of them staged pictures for the website.

I was thinking I’m going to get them up on the website next week. This is going to be a success. I come down the next morning.The trays are sitting on this table and this is how I find them.

So that’s not good. Obviously there was some kind of tension in the board and then, when I cut out that material it cupped, so I reached out to the manufacturer and asked them What do you think is going on here .

They said that can happen and they were working with their manufacturer to work out the problem, so I sent him the pictures and I haven’t heard back yet.

As of right now have to kill this idea. I’m just not confident in it .I don’t want returns and that’s part of prototyping.

Encourage

I was sitting on the porch with my wife one night. After I had told her all of this and the great sounding board that she is. I was discouraged and she was like well why don’t you make your own plywood.

I was like well,I had thought of that is really hard and I probably have the same problems because of the compression and gluing.

All that I was just giving a bunch of excuses. Because I was kind of giving up on the idea. She was like talking about why don’t you make it out of hardwood layers ?

I thought , you’re not going to be able to get the 16th or 8th inch layers that you were looking for, but you still could make some cool designs. For example layering walnuts with exotics like padauk or purple heart.

So I did a little research and there’s not any of that out there right now. with her incur, encouragement and idea, I’ve started that prototyping process.

Why It Is Different Than Started

You’ll find my step-by-step guide a little bit different than my current approach, and that’s because I’ve been working with wooden trays for like three years, so that is a little bit different than just getting started.

That’s why I wanted to design a step-by-step guide on how to get started making CNC products. because once you get started, you really get that ball rolling and you learn what works and what doesn’t work and you continue to learn what doesn’t work, but that evolves over time again.

So if you have any other problem about CNC Router, just contact us to get more details.