Today we’ll be taking a look at wood shaper, which is also called woodworking spinldle moulder.

The key components of them, their capabilities, and some add-on accessories that can help make this the cornerstone of your shop.

A shaper is essentially a beefed up router table that enables you to do larger production runs of millwork.

It is trims and profiles, as well as things like cabinet door construction in bulk.

Why Choose Wood Shaper/ Spindle Moulder?

Motor

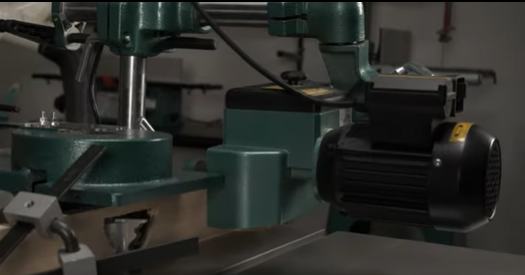

They’re built around a dedicated motor with more torque than a smaller router, which makes taking larger cuts possible.

That powerful motor also can run larger cutters than most router tables.

The motor which I’ll show you here drives the belt, and you can see that there are actually two speed options based on the motor pulley for this machine.

The belt is connected to the spindle housing and the spindle itself, so let’s take it to the top side and look at the spindle.

Different Sizes of Spindle

Looking down through the table insert you’ll see the spindle.

The shaper comes with several sizes of spindle, which is another benefit to the shaper’s capacity.

Larger spindle options allow you to run larger cutters, which provide more rigidity during heavier cuts.

The spindle itself is held in place with a drawbar and a nut that is below the table.

To change out your spindle, simply unthread the drawbar nut, remove the spindle and draw bar.

Then re-insert the draw bar into a new spindle, ensuring that you have 10 to 15 threads.

Reinsert it, put the nut back in place, and you’re ready to go.

I just want to point out that router tables and shapers both have a place in the wood shop, and often overlap in their capabilities.

Routers can be great for smaller profiles and can also be used for larger profiles.

They just may require more passes to do it.

Heavy Duty Cast Iron Fence

Shapers typically have a pretty robust fence setup and this one is a heavy duty cast iron fence.

The fence on either side of the cutter head is movable so depending on the cutter profile being used you can unlock this fence, rotate the knobs on top to move them inside and out to the desired offset, then lock it back down.

As you can imagine dust collection is a big part of using the shaper, and you’ll want to connect a collector with at least 400 cfm.

Now having a large flat work table is a big part of shapers as well, because of the different kinds of work pieces you’re likely to run through.

For large door panels having a larger table adds a lot of support and safety, especially on those end grain cuts.

Shaver Grand Tour

Next on our shaver grand tour is the front of the machine, or the control panel if your machine has a dedicated pedestal.

Out front you’ll see that there is a spindle height hand wheel, and a height scale, and to the side is the magnetic switch with the on off and reversing switch.

Not every machine will come with a reversing switch, but it can be a handy thing for specific types of wood where running material in the forward direction can cause you excessive tear out, or if you want to flip the cutter upside down.

Now we highly recommend that you take extra precautions if you intend to do a cut in the reverse position, using as many safety measures as possible including a power feed for the best results.

Feeder

Now a power feeder is a great safety device to keep your hands away from the cutter head.

Its main purpose is to smoothly and consistently feed your material through, while also keeping pressure down on the table and against the fence.

That helps ensure that you have a nice even profile on your work piece, plus you can run a lot of material very quickly for projects like base molding or crown molding.

You may have noticed that this machine is actually mobile, and that can make a big difference when you’re operating in a smaller shop.

When you have multiple shapers each set with a specific cutter task, and you’re swapping between them as necessary.