Description

Full-automatic edge banding machines eb360dj for woodworking

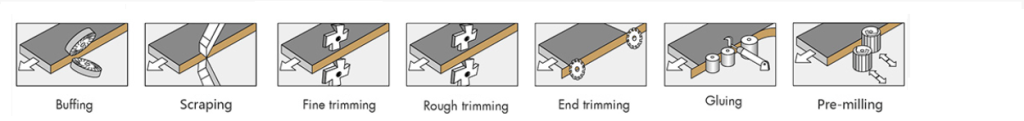

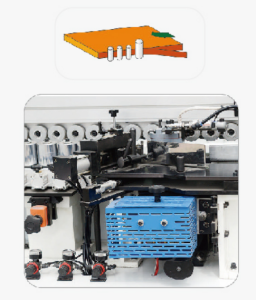

The Edge banding machines EB360DJ consists of 7 automatic stations, which are MDF-bonded during the passing process. All of the parameters that characterize this device, and the quality of its components ,is a machine that delivers a better quality of workpiece at the lowest possible cost. Hence, the edgebanding machine EB360DJ has become a popular machine in the wood industry.

The high level of automation of the stations reduces human intervention to the lowest possible extent, resulting in a process of human exclusion. How to perform operations, such as adjusting the conveyor to the switch between the three speeds of 12, 16 and 21 meters per minute, can be controlled through the control panel of the device, which is a touch screen by executing programs through the PLC. The preheating system is embedded on the device, the workpieces temperature will be increased to a degree that makes bonding the tape easier to work so that the precision is higher and the work surface reaches the highest possible quality.

Specification

| MODEL | edgebender machine |

| Motor power | 11.5kW |

| Overall size | 5800x1100x1600mm |

| Feed speed | 12-20m/min |

| Panel thickness | 10-60mm |

| Edge bading tape thickness |

0.4~3mm |

| Panel width | >40mm |

| Working pressure | 0.8MPa |

| Weight | 2500Kg |

Feature

Using imported quality engines and electric components.

Adopt to the linear sealing of PVC,wood plank and veneer etc.

Serialized products,a wide range of selection by customers.

High precision and efficiency

|

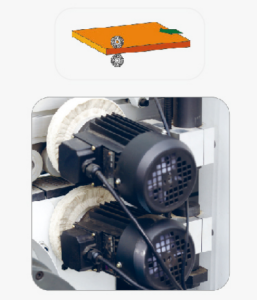

The buffing device adopt the board processed by cotton polishing wheel, by end polishing to make a more smooth surface. |

|

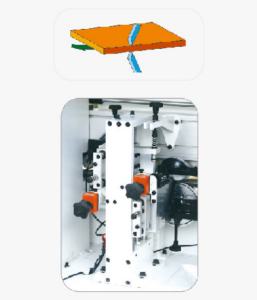

Scraping unit for a perfect finishing of the applied edge. |

|

Rough/Fine trimming mecha nism used for repairing the excess edge materials, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the trimming plates smoothly. |

|

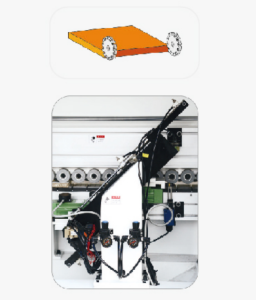

End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly. |

|

Trim equipment with double trim-blades works on the waved effect that is caused by precise saw. |

|

The glue mechanism adopt a special structure to gelati nize the plates and coating materials uniformly, ensure a more solid conglutination. |

Advantages

1. Almost tewenty years of producing experience on corner rounding edge bander machine;

2. Diamond premilling blade;

3. CE certificate is available which is issued by Germany TUV;

4. The efficient, highly flexible machine series for edge banding.

5. Ideal for all kinds of edging material: Solid wood, melamine, PVC and veneered edges, fixed length and coil material, for banding with hot-melt.

6. Color and cover can be customerized as per your requests. OEM is available for us.

7. Here is the original maker for edge banding machines .

Applications

Full automatic edge banding tape machine is used to edge banding pvc or wood veneer onto board sides, like MDF boards. Us woodworking machine manufactures to make the furniture more beautiful and envirenment friendly.

Delivery & Packing

.We will take care of your edgebander machinery packages well like picture show.

·Our workers will make sure your machine clean before package.

·We will add stretchy film for the whole machine and spare parts for delicate protection.

·We will make export standard strong Wooden box case package as your request.

More about furniture making woodworking machine mini automatic edgebanding machine/edgebander machine,Feel free to contact us.