It’s uncommon to hear a story of someone

who has recently purchased a desktop CNC Router.

Now they find themselves frustrated overwhelmed and ready to give up.

Since I often talk about making money with your desktop CNC router.

I want to take a step back from that and paint a clear picture on what to expect when first getting started with the CNC machines.

So let me start by saying this post is not to determine who should own a CNC machine and who shouldn’t own a CNC machine. Rather it’s to lay out the information of what it takes to get started in CNC machine.

Then, knowing this information, you can make the correct decision for yourself.

Let’s start right from the beginning of the 6090 desktop CNC router.

Budget

Let’s talk about budget. I recommend a budget of 3000 dollars to get started in a 6090 desktop CNC router.

That’s approximately 2500 dollars for the machine itself. There’s a lot of different brands and variances, but 2500 for the machine itself and then 500 for any accessories that you’ll need to operate the machine.

Now you can do it for less, but I don’t recommend it.

At that 3000 price point, it will get you into a well-built more than capable machine for the beginner.So you hit that order button and your machine is on its way.

Getting Prepared

There’s a few things that you need to be doing during this time period before your machine arrives.

Building A Place for Your Machine

The first one is building a table or some kind of flat, stable surface that your machine will sit on.

Download the Software

The second one is downloading the CAD CAM software that is recommended by the manufacturer that you purchased your machine from. This is a great time to start designing and playing around with the software and getting familiar with it.

Purchasing Accessories

Another thing you can be doing during this time is purchasing any additional accessories that you may need.They include things like work holding and end mills and those types of things.

Watching Useful Video

The fourth thing you can be doing – which I highly recommend is spending time watching Youtube videos. But there’s a trap here, don’t watch with the intent of just looking at the different things that you could build.

Most likely those projects that you’re watching aren’t from people that are just starting out with their CNC Routers. You’ll see someone on Youtube making a project that you’re not necessarily capable of yet. And you’ll get really defeated and really discouraged when you go from excitement to I’m not capable of that yet.

When I say watch Youtube videos with the intent of learning your software, workflow in the processes and learning people’s setups.

CNC Assembly

When your machine arrives. Most likely it’s arrived in several boxes that now you need to unpack and assemble yourself. Yes, at this price point some assembly is required.

I would recommend setting aside a day for you to assemble and set up your machine. This is going to involve reading the instruction booklet closely. A lot of hex wrenches and m5 screws.

Another thing you’ll have to do is square and level your machine once you get it all assembled. So now that your machine is all assembled, it’s time to throw a piece of wood on it, hit play and make something Cool.

CAD and CAM

Not quite so fast now we need to dive into the CAD and CAM side of the CNC. So let’s take this CAD CAM and break it down.

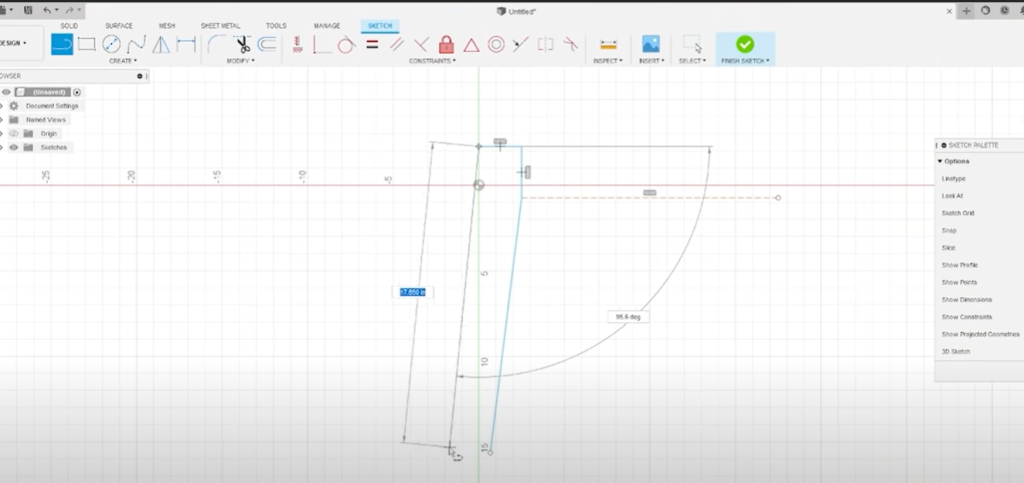

CAD

Let’s talk about CAD first. When you hear CAD, think of design, it’s computer aided design.

So in your CAD software, this is where all your designs are made. Think artwork, like I said earlier, I’d recommend, starting with the software that your CNC manufacturer recommends. This is the easiest and shortest learning curve when you’re first getting started.

CAM

So now, let’s quickly jump into CAM.

CAM is computer-aided manufacturing. CAM is what generates the G-code in which your CNC reads to cut out your design. This is where tool paths, feeds and speeds come in.

The really cool thing that’s often overlooked with desktop CNC Routers is most manufacturers have developed their own software that goes with their CNC machines. And they’ve combined both CAD and CAM softwares together to make one.

So you actually design and do the tool paths so you’ll do the CAD and then the CAM in the software, and then it generates a file that your CNC can read and make your design.

These companies realize they need to make the software as user friendly as possible with still having functionality. As you get comfortable with this software, you can move on to other software that have more capabilities. But there’s no reason to start there. Some of the more popular CAD km softwares are programs like VCarve PRO、 Carbide create Easel and Fusion 360.

The other thing you’re going to have to wrap your head around is feeds and speeds.

This is how fast your machine is cutting and moving. Now, I’m generalizing here, but this includes things like inches per minute or IPM. Your depth of cut your RPMs.

The good thing about this is that there should be some pre-loaded settings for the bits that you’re using in the software that you’re using and if there isn’t there’s usually information on the bit manufacturer’s website to get an idea here.

Keep in mind that speeds and feeds for wood is going to be a range. Wood is extremely forgiving, and just remember that the perfect feed rate is not too fast, not too slow.

You want to be making wood chips and not wood dust .

What Do I Make

On the CAD side of things.What are we going to make one common way around. This is to purchase design files. These files are our vector files, so you want to be looking at things like .SVGs and DXFs.

Now remember just because you purchased the design files, it doesn’t come with the tool paths.The tool paths are something that you’re going to have to learn on your own, because there’s so many variables between machines, tools and materials.

So this is really where things come in and they can get tricky, but this is just experience. The good thing like I said about wood is that it’s extremely forgiving and with a few trial and error pieces. You’ll get the hang of it.

A couple places you can find these design files etsy is a popular place. I even have some design files on My website, like everything else that I mentioned in this post , I’ll leave a link to my website and all the other resources down in the description below for you to refer to.

What Else Do I Need?

So here’s a list of other things you’ll need besides your CNC machine.

Need Things to Control CNC

You’re going to need some way to control it, meaning you’re gonna need a computer of some sort of tablet that will be able to control the CNC.

End Mills

You also need a set of end mills or also referred to as bits. I wasted a lot of money at the beginning when I was getting into CNC, because I didn’t know what bits I needed. So would just buy bits and then I would use them or they weren’t the right ones. So what I’ve learned is I narrow it down just starting out to start with these three bits.

You start with a quarter inch up cut bit, start with a 60 degree v bit, and you start with a bowline tray bit. I do 75 of my work with those three bits.

If you have a project in mind to do something specific, it may require different bits. But I recommend those three to get started because you’re always going to use them and there’s a lot of versatility there.

Work Holding

Another thing you’re going to think about is work holding. Work holding is what holds your piece of wood to your waste board while it’s being machined.

There are a lot of ways to accomplish this and it comes down to kind of user preference and what you’ll be making. What I typically do for a project that is a cut out of something.

I will screw the piece of wood to my waste board with deck screws. If I’m doing a more delicate piece and not and doing some engraving or something like that, I’ll use double-sided carpet tape.

Dust Collection

The last thing to consider is dust collection. This one is often overlooked, but these CNC machines do create a lot of dust.

So one thing you’ll need to get is a dust boot that goes around your router, where your dust hose will connect to it. Now, dust collection for the CNC machining , just starting out, can be as simple as a shop vac. Now, that’s not probably a long-term solution. But for a desktop CNC router starting out that is acceptable.

Again ,this post isn’t to intimidate anybody from jumping into CNC routers head first. The truth is depending on your background, the first couple months of owning your CNC machines could be filled full of a lot of trial and error.

But with all the resources out there, I believe that anyone who commits to learning who is willing to fail and has a little patience can be successful, operating a CNC.

My hope is that by painting this clear picture, you’ll know what to expect when heading down the path of CNC router. For the first time. I’ll leave all of the helpful links that I referred to in this post down in the description below.