Edge banding quality of edge bander is influenced by many internal and external factors which including equipment condition, raw material condition, and operation skilled.

Edge bander manufacturer(WINMAX)suggest below conditions should be more attention at any time.

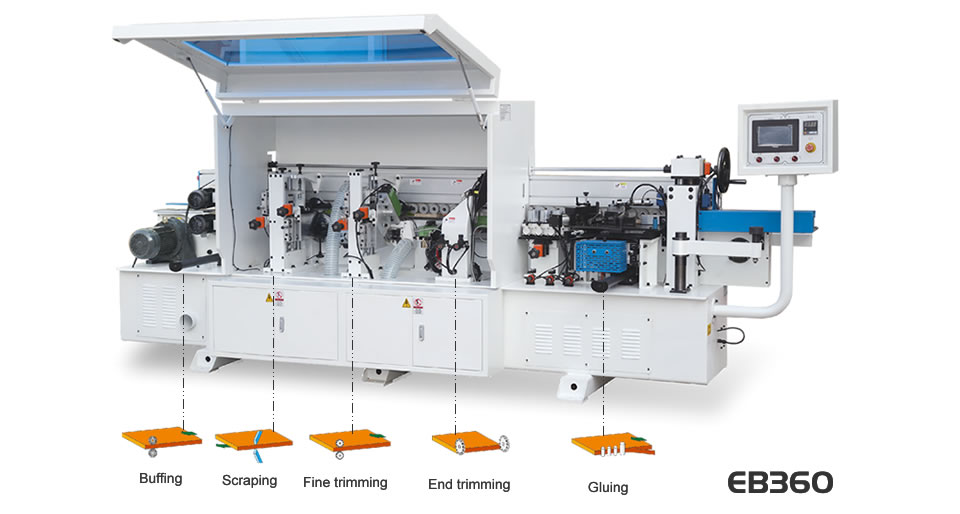

Six key conditions for edge banding quality control

1. Press roller position

When you use a thick edge band for banding, press roller should in the best position as most problem is owing to pressure too tight.

As the edgeband is longer compared to the workpiece, when the feeding roller presses the extra part of edge, which apply force perpendicular to the direction of the feed to the edge band.

At this time the glue is not completely cured, the bonding strength is not high the tail and releasable adhesive are not strong.

2. Temperature and edge band quality

The indoor temperature can not be too low when machining, in general, should be more than 15°C.

Especially with a thick edge, flexibility will be insufficient, which need to ensure the normal operation of the preheating device.

Without preheating device, hairdryer heating also can be use to make edge softening.

This method is especially suitable to the curve edge.

There shall be no draught in the processing workshop.

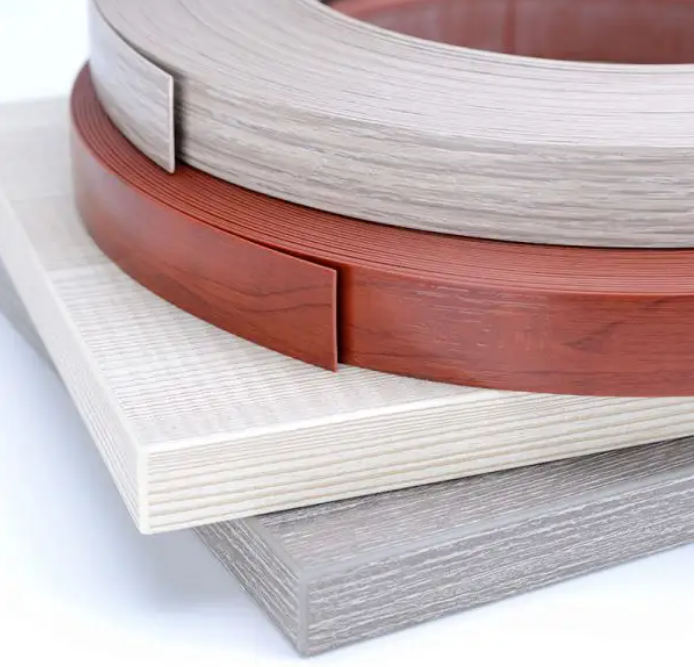

The edgeband influences edge banding quality.

Good quality edge sealing tape sealing out of the product edge tight.

Good quality edge band with edge sealed products at the tight edge.

The edge of the poor quality of the product edge of the gap is larger, also there is an obvious black line.

When edge trimming, the backer is easy to scratch the mark on the surface.

Check the edgeband from the section, the middle of the adhesive surface should be slightly more concave than both sides, this edge sealing product edge sealing is more rigorous, the effect is good.

3. Moisture of wood

Moisture content of solid wood edge sealing material should not be too high.

It should be stored in a cool and dry room, the base material requires no dust, the best moisture content in 8-10%.

4. Adhesive for edge banding

Because the edge sealing speed is very fast, the adhesive in low pressure to have a good dispersion and permeability to the base material, to have a good initial viscosity, in a short time of pressure should be instant gluing, bonding firm.

When using, we should pay attention to ensure that the temperature of hot melt adhesive is within the normal temperature range, too high temperature for a long time will make the adhesive points; Low temperature hot melt adhesive can not achieve good fluidity, use to master the data provided by the supplier.

5. Glue control for edge banding

The amount of hot melt glue should be slightly extruded outside the adhesive parts, too much, there is a black line at the edge, affecting the appearance;

Too little, not enough adhesive strength.

In order to test whether the film is continuous, you can use transparent hard PVC test;

You also be used ordinary edge sealing tape edge sealing, while the glue is not cooling off the edge sealing tape to test.

6. Semi-finished quality before edge banding

To the edge bander manufacture wihch without premill cutter device , the semi-finished cutting quality also affect edge sealing effect.

In order to prevent the product from bursting, the general manufacturer will use the notch saw (commonly known as the small saw blade) when cutting.

The best effect after cutting should be to see the small saw blade mark at the section but not feel it.

Small saw blade mark is too deep edge sealing is not secure, edge sealing can see a black line or even see gaps, too shallow and explosive mouth.